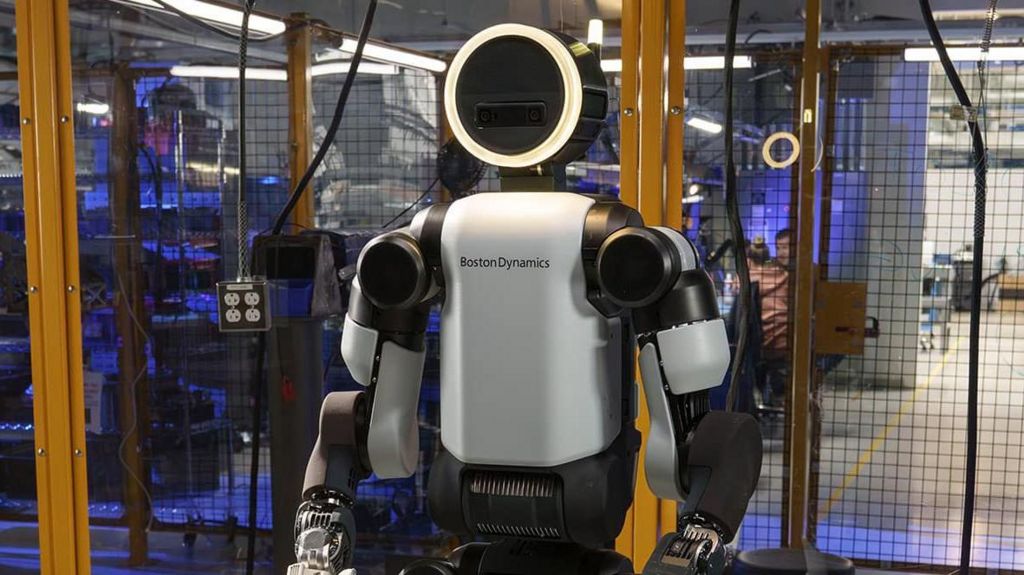

In a significant advancement for industrial automation, Hyundai Motor Group has announced plans to deploy humanoid robots at its manufacturing facility in Georgia, United States. The revelation came during Monday’s Consumer Electronics Show (CES) in Las Vegas, where the South Korean conglomerate showcased Atlas—a bipedal robot engineered by Boston Dynamics, in which Hyundai holds a controlling interest.

This strategic move positions Hyundai alongside industry pioneers including Amazon, Tesla, and Chinese automotive titan BYD, all actively integrating humanoid robotics into their manufacturing ecosystems. The Atlas robots are scheduled to commence operations in 2028, with a phased implementation approach designed to gradually expand their operational capabilities within the production environment.

Engineered for versatile industrial applications, Atlas represents the next generation of collaborative robots designed to operate synergistically with human workers while autonomously managing machinery. Hyundai emphasizes that these robotic systems will mitigate physical strain on employees, undertake high-risk tasks, and accelerate the broader adoption of advanced automation technologies.

Hyundai’s announcement carries particular significance given the Georgia plant’s history. In September 2025, the facility became the center of a substantial immigration enforcement operation resulting in hundreds of detainments, including approximately 300 South Korean nationals. The incident provoked diplomatic tensions and raised concerns about foreign investment climate in the United States.

The robotics initiative aligns with Hyundai’s substantial $20 billion investment strategy in the U.S. market, announced in 2025, which supports domestic manufacturing expansion while advancing autonomous driving and artificial intelligence capabilities. Company executives, including Vice Chair Jaehoon Chang, have acknowledged workforce automation concerns while emphasizing the continued need for human expertise in robot training and supervision.

While Hyundai has not disclosed specific financial details or initial deployment quantities, this development marks a pivotal moment in industrial robotics, potentially establishing new benchmarks for manufacturing efficiency and human-robot collaboration in post-pandemic industrial landscapes.