China has marked a monumental advancement in space technology by successfully executing its inaugural metal 3D printing experiment in orbit. This pioneering achievement represents a critical transition from terrestrial research to practical space-based engineering verification, positioning China at the global forefront of in-orbit manufacturing capabilities.

The groundbreaking experiment was conducted using a specialized retrievable scientific payload developed by the Chinese Academy of Sciences’ Institute of Mechanics. The equipment traveled aboard the Lihong-1 Y1, a commercial recoverable suborbital vehicle engineered by CAS Space primarily for space tourism applications. On January 12th, the spacecraft launched from the Jiuquan Satellite Launch Center in northwest China, reaching an altitude of approximately 120 kilometers and crossing the Kármán line—the recognized boundary between Earth’s atmosphere and outer space.

Upon achieving microgravity conditions, the system autonomously fabricated metal components, overcoming extraordinary challenges unique to the space environment. Researchers conquered complex obstacles including stable material transport in weightlessness, full-process closed-loop control systems, and seamless coordination between the experimental payload and launch vehicle.

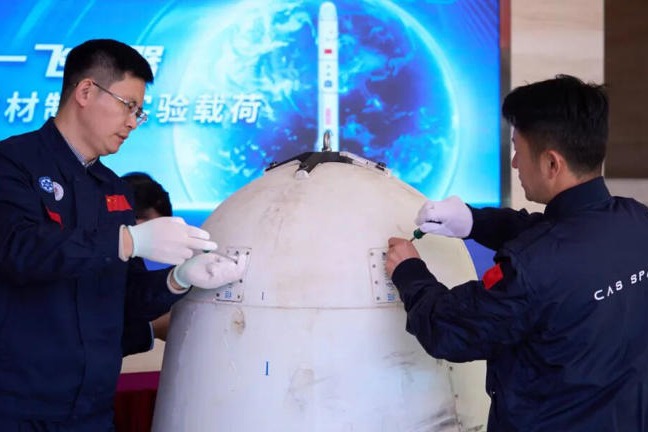

Following the mission, the payload capsule safely returned to Earth via parachute-assisted landing, enabling scientists to recover invaluable data on melt pool dynamics, material transport mechanisms, solidification behavior, and the geometric precision and mechanical properties of space-manufactured components.

The Lihong-1 Y1 vehicle, celebrated for its cost-effectiveness and operational flexibility, demonstrated its viability as a platform for scientific experimentation. Beyond the 3D printing apparatus, the mission also transported precious rose seeds for agricultural research purposes.

According to deputy chief designer Wang Yingcheng, ongoing development focuses on incorporating crew-life-support systems and high-reliability escape technologies, potentially enhancing both low-cost suborbital research capabilities and commercial space tourism prospects. This breakthrough establishes a foundation for future space infrastructure development and advanced manufacturing operations beyond Earth’s atmosphere.